-

Parameters

-

Comments

| ZrO2,%≥: | 33-40 | Bulk Density(g/cm3):: | 3.5-3.9 |

|---|---|---|---|

| Cold Crushing Mpa: | 350 |

Special Shaped Corundum Mullite Insulating Refractory Bricks With Acid Resistant

Quick Detail:

♦ Compact microstructure

♦ Good erosion resistibility to molten glass

♦ Good thermal shock resistibility

♦ Barely rendering blister

Applications:

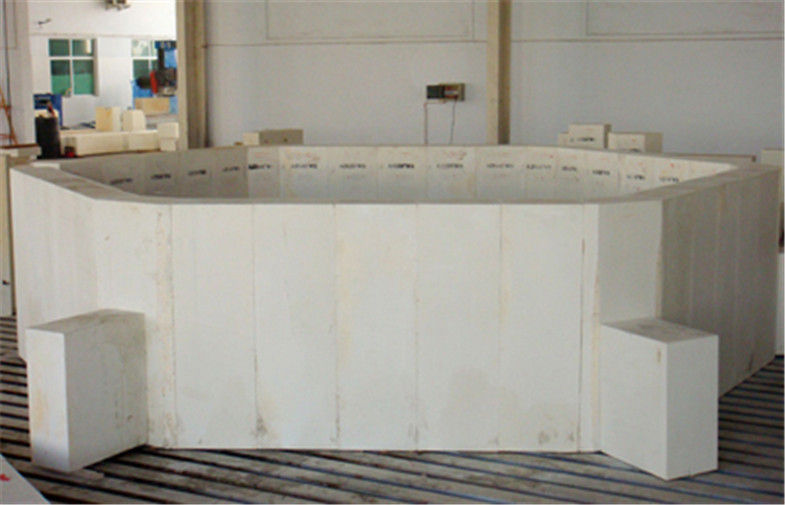

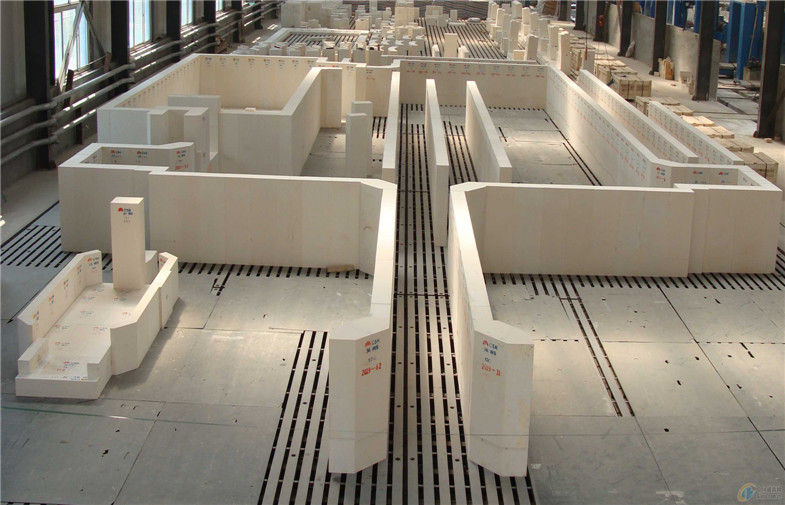

mainly used for side walls of flame furnaces with embedded melter bottoms, for total security with average pulls and campaign lengths, and superstructures, front wall, back wall, top crown in glass melting furnace.

Specifications:

|

chemical composition |

AZS-33 |

AZS-36 |

AZS-41 |

|

ZrO2 |

≥33 |

≥35 |

≥40 |

|

SiO2 |

≤16.0 |

≤14 |

≤13.0 |

|

Al2O3 |

a little |

a little |

a little |

|

Na2O |

≤1.5 |

≤1.6 |

≤1.3 |

|

Fe2O3+TiO2 |

≤0.3 |

≤0.3 |

≤0.3 |

Physical Properties

|

bulk density(g/cm3): |

3.5-3.6 |

3.75 |

3.90 |

|

|

cold crushing Mpa |

350 |

350 |

350 |

|

|

thermal expansion coefficient (1000°C) |

0.80 |

0.80 |

0.80 |

|

|

exudation temp. of glass phase |

1400 |

1400 |

1400 |

|

|

corrocion resistance of glass melt(mm/24h) |

1.6 |

1.5 |

1.3 |

|

|

Density |

PT QX |

3.40 |

3.45 |

3.55 |

|

WS ZWS |

3.60 |

3.70 |

3.8 |

|

phase composition(%)

|

baddeleyite |

32 |

35 |

40 |

|

glass phase |

21 |

18 |

17 |

|

α- corundum |

47 |

47 |

43 |