-

Parameters

-

Comments

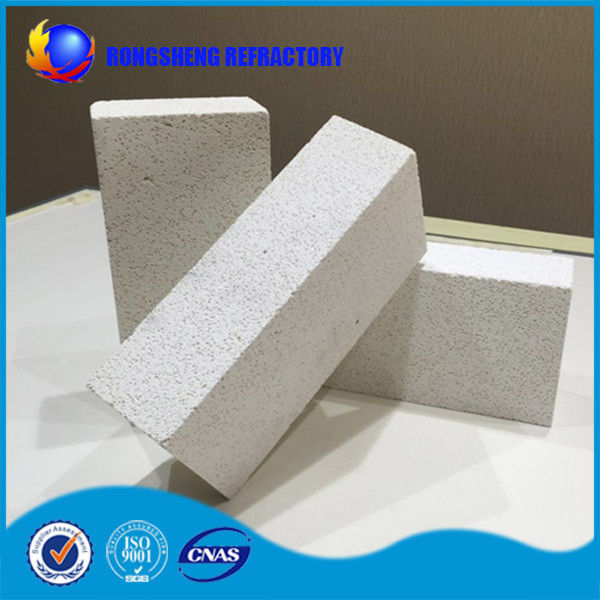

Silica mullite brick Refractory Products apply cooler and hoops in cement industry

Description:

High quality silica mullite brick for cement kiln

1. Thermal shock resistance;

2. high strength;

3. good wear resistance.

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

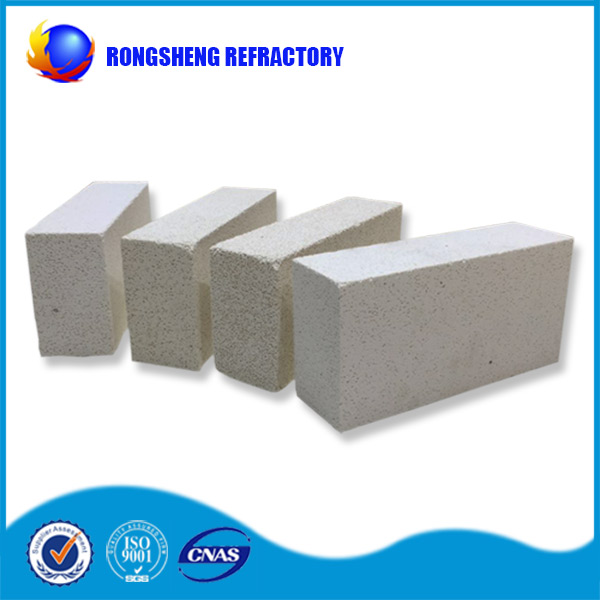

Specifications:

physiochemical index

Silica Mullite Brick

|

|

Product |

AZM-1550 |

AZM-1650 |

AZM-1680 |

|

Index |

|

Index |

Index |

Index |

|

chemical composition |

SiC+SiO2 |

≥35 |

≥30 |

≥32 |

|

Al2O3 |

≥60 |

≥65 |

≥65 |

|

|

Bulk Density(g/cm3) |

≥2.55 |

≥2.65 |

≥2.70 |

|

|

Apparent Porosity (%) |

≤20 |

≤19 |

≤19 |

|

|

Cold Crushing Strength(Mpa) |

≥80 |

≥90 |

≥100 |

|

|

Refractoriness Under Load |

≥1550 |

≥1650 |

≥1680 |

|

|

Thermal Shock Resistance |

≥10 |

≥15 |

≥20 |

|

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation