-

Parameters

-

Comments

Shaped Dry Pressed Kiln Refractory Fire Bricks Insulating Fireclay Block

Description:

Refractory Bricks For Ladle Flow

Feature:

1. bricks are made from high quality bauxite

2. dry pressed

3. burned under tunnel kiln

4. accurate dimension

5. high strength

Product specification:

standard form, normal standard, shaped and special shaped bricks.Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the mostly used in the key positions.Molding method: it has down draft kiln and tunnel kiln and the general sintering temperature is 1360-1480 degrees. It is a kind of aluminosilicate refractory product which aluminum oxide (Al2O3) content is higher than 48%.

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Specifications:

Physical and chemical indexes:

|

Item/Grade |

Fire clay brick |

High alumina brick |

||||||

|

SK-30 |

SK-32 |

SK-34 |

SK-35 |

SK-36 |

SK-37 |

SK-38 |

SK-40 |

|

|

AL2O3% (≥) |

30 |

35 |

38 |

45 |

55 |

65 |

70 |

82 |

|

Fe2O3% (≤) |

2.5 |

2.5 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

|

Refractoriness(SK) |

30 |

32 |

34 |

35 |

36 |

37 |

38 |

40 |

|

Refractoriness under load, 0.2MPa, °C (≥) |

1250 |

1300 |

1360 |

1420 |

1450 |

1480 |

1530 |

1600 |

|

Apparent porosity (%) |

22-26 |

20-24 |

20-22 |

18-20 |

20-23 |

20-23 |

20-22 |

18-20 |

|

Bulk density (g/cm³) |

1.9-2.0 |

1.95-2.1 |

2.1-2.2 |

2.15-2.22 |

2.25-2.4 |

2.3-2.5 |

2.4-2.6 |

2.5-2.7 |

|

Cold crushing strength ,MPa (≥) |

20 |

25 |

30 |

40 |

45 |

50 |

60 |

70 |

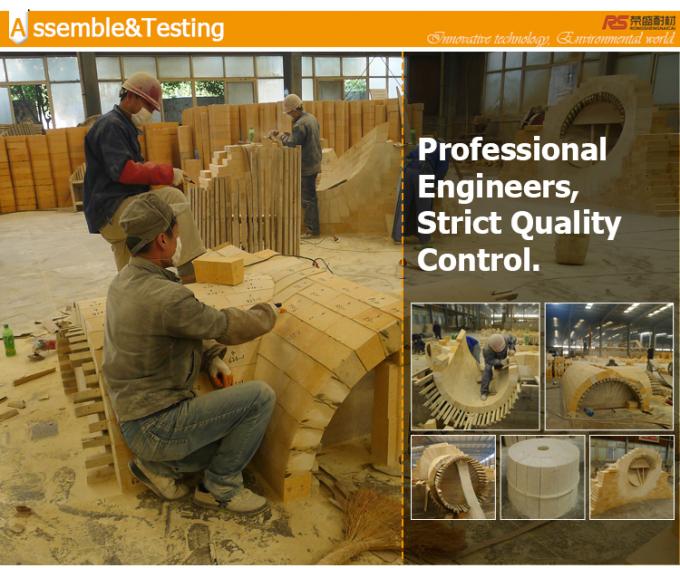

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation