-

Parameters

-

Comments

| Aluminum Content: | ≤75% | Apparent Porosity: | ≤20% |

|---|---|---|---|

| Cold Crushing Strength: | ≥60MPa | 0.2MPa Refractoriness Under Load: | ≥1500℃ |

| Permanent Linear Change On Heating 1500℃*2h: | 0.1~0.4 | Name: | Ceramic Refractory Bricks |

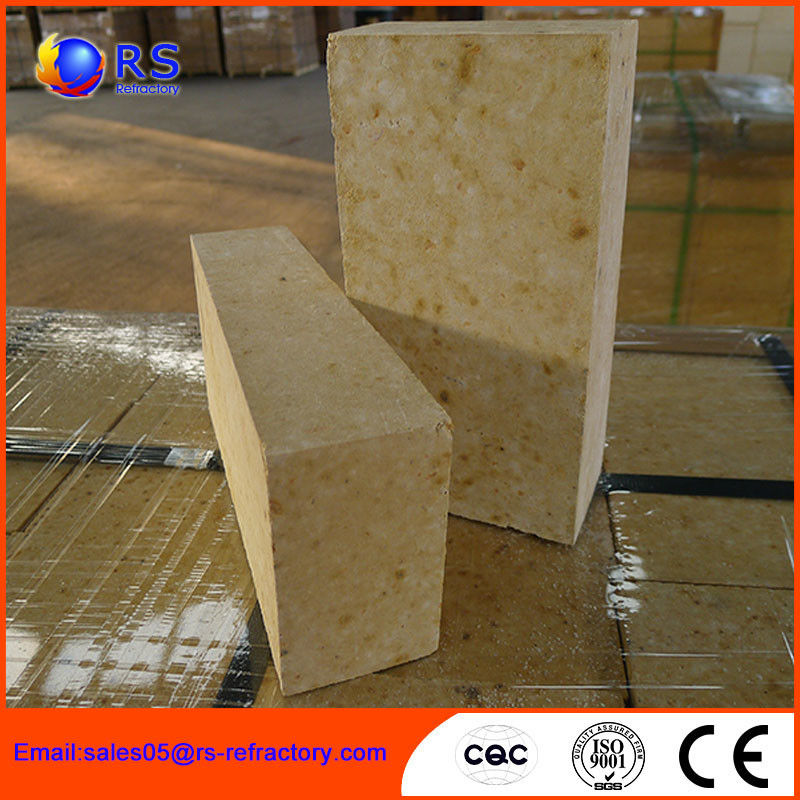

Professional High Alumina Refractory Brick For Cement Industry / Hot Blast Stove

Description:

By alumina or other higher raw material forming and calcined alumina content. Thermal stability, high refractoriness in more than 1770 ℃. Good slag resistance, used for building steel-making furnace, glass furnace, cement rotary kiln lining.

Features:

1. High refractoriness

2. good slag resistance

3. high refractoriness under load

AppLication:

Mainly used in lining of blast furnace, the hot blast stove, electric furnace roof, furnace and reverberatory furnace, rotary kiln lining. In addition, high alumina brick,widely used for open hearth regenerative checker brick, pouring system with the plug head, nozzle brick, etc.

Phycial and chemical index:

| Items | RSGL-75 |

| AL2O3,%,≥ | 75 |

| Fe2O3,%,≤2.0 | 2.0 |

| Apparent Porosity % ≤ | 20 |

| Bulk density g/cm3 ≥ | 2.5 |

| Cold Crushing Strength MPa ≥ | 60 |

| 0.2MPa Refractoriness Under Load ℃ ≥ | 1500 |

| Refiring linear change 1500℃*2h,% | 0~-0.2 |

| Refractoriness ℃ ≥ | 1790 |

Product pictures: