-

Parameters

-

Comments

| AL2O3: | ≥70% | Bulk Density: | ≥2.6g/cm3 |

|---|---|---|---|

| Apparent Porosity: | ≤18% | Cold Crushing Strength: | ≥90MPa |

| Name: | Insulating Fire Brick |

JM23 JM26 Mullite Refractory Bricks , Insulating Fire Brick For Rotary Kiln Lining

Description:

It is mainly used in hot blast furnace roof, blast furnace body and bottom, glass melting kiln storage chamber, ceramic sintering kiln, oil cracking system dead Angle furnace lining.

Features:

1. High structure density,

2. Low porosity

3. Good erosion resistance.

Composition:

1. The sintered mullite brick is made of high bauxite as the main raw material, with a small amount of clay or bauxite

2. The combination is made of molding and sintering. It is used as raw material with high bauxite, industrial alumina and refractory clay

3. The reagent is used to manufacture after forming.

Physical and chemical index:

| Items | Mullite | |

| AL2O3%≥ | 70 | |

| Bulk Density g/cm3≥ | 2.6 | |

| Apparent Porosity≤ | 18 | |

| Cold Crushing Strength≥ | 90 | |

| Thermal Shock Resistance | 25 | |

| 0.2MPa Refractoriness Under Load | 1500 | |

| Thermal conductivity | 2.5 | |

| Rervice Temperture | 1550 | |

| Refractoriness | 1790 | |

| Wear-resisting Degree | 8 |

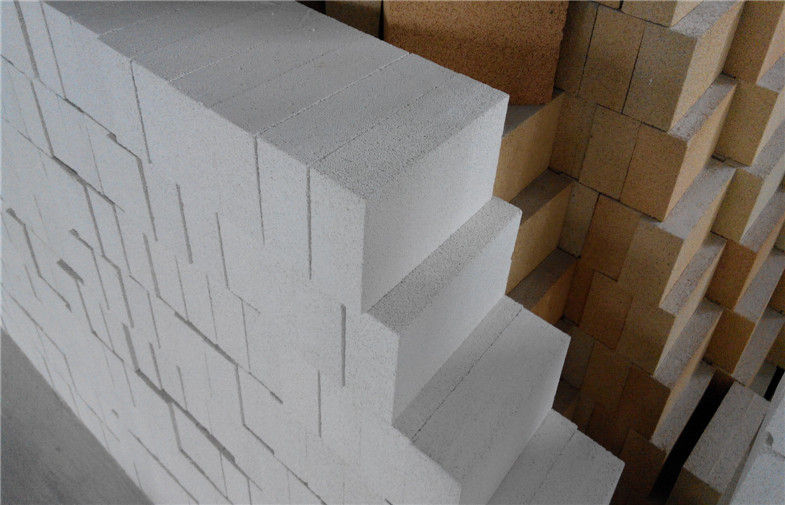

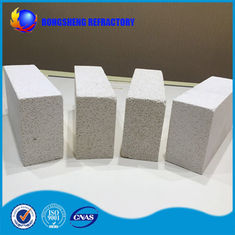

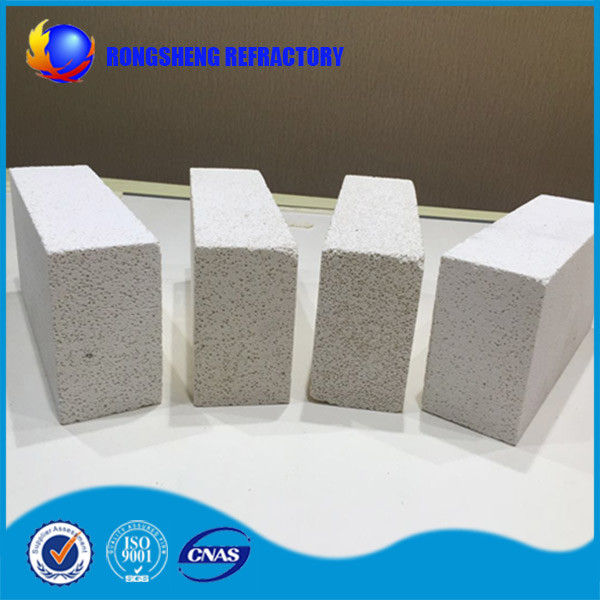

Product Pictures: