-

Parameters

-

Comments

| Al2O3 %: | ≥55 | SiC %: | ≥4 |

|---|---|---|---|

| C %: | ≥12 | Apparent Porosity %: | ≤15 |

| 0.2Mpa Refractoriness Under Load °C: | ≥1600 | Cold Crushing Strength Mpa: | ≥25 |

| Modulus Of Rupture/Mpa: | ≥9 | Bulk Density G/cm3: | ≥2.5 |

| Average Thermal Expansion (1000°C): | 2.4×10-6 |

Insulating Fire Furnace Bricks , Burned Micro porous Alumina carbon Bricks Al2O3 55%

Alumina-carbon brick used superfine calcined bauxite and sintered or fused corundum sand as main raw material and added composite graphite powder has received very good use effect of iron powder erosion resistance, carbon powder erosion resistance and atmosphere scour erosion resistance.

Feature:

1.High hardness,high mechanical strength,

2.High temperature of refractoriness under load,

3.Good thermal shock resistance and slag resistance,

4.Strong corrosion resistance,

5.Strong resistance against alkaline substances,

6.High thermal conductivity,low thermal expansion,

7.Good thermal shock resistance.

Application:

Alumina-carbon brick is widely used in blast furnace,hot metal ladle,sliding gate brick,steel ladle,tundish,ladle shroud,submerged nozzle,monoblock stopper for continuous casting of blooms.

Technical Date:

| Item | Alumina carbon brick | |

| Al2O3 % | ≥58 | ≥55 |

| SiC % | ≥5 | ≥4 |

| C % | ≥14 | ≥12 |

| Apparent Porosity % | ≤13 | ≤15 |

| 0.2Mpa Refractoriness Under Load °C | ≥1630 | ≥1600 |

| Cold Crushing Strength Mpa | ≥30 | ≥25 |

| Modulus of rupture/Mpa ≥ | ≥12 | ≥9 |

| Bulk Density g/cm3 | ≥2.5 | ≥2.5 |

| Average thermal expansion (1000°C) | 2.4×10-6 | 2.4×10-6 |

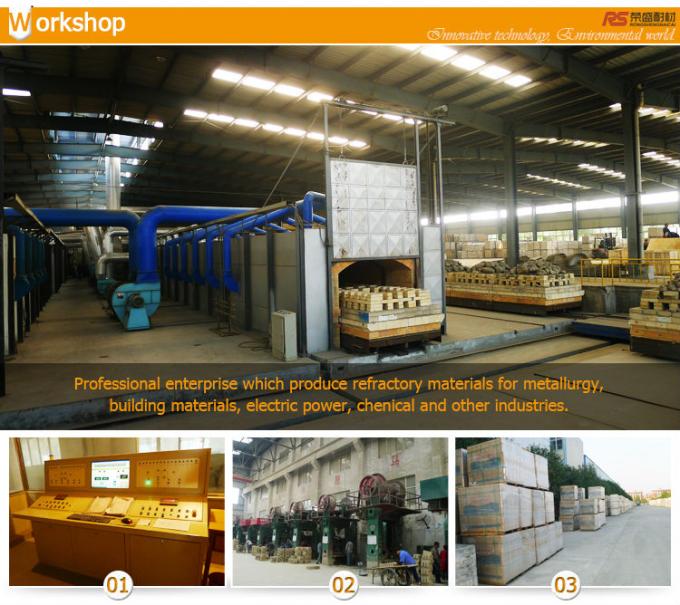

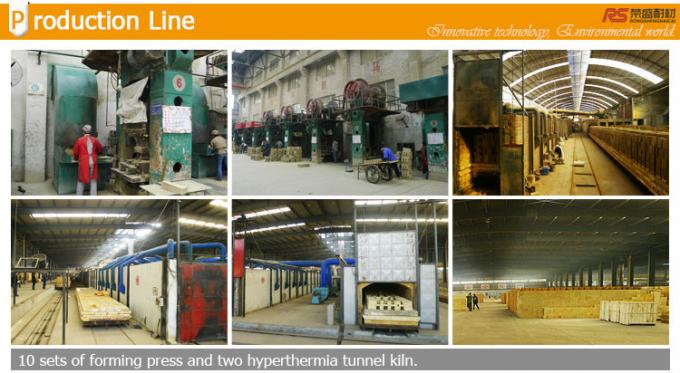

Company Information:

Zhengzhou Rongsheng Refractory Material Co., Ltd. is located in the hinterland of Central Plains, at the foot of Songshan Mountain, and adjacent to Zhengshao Highway, Longhai and Jingguang railways. The convenient transportation, abundant resources and high quality minerals provide favorable conditions for the production of refractory materials.