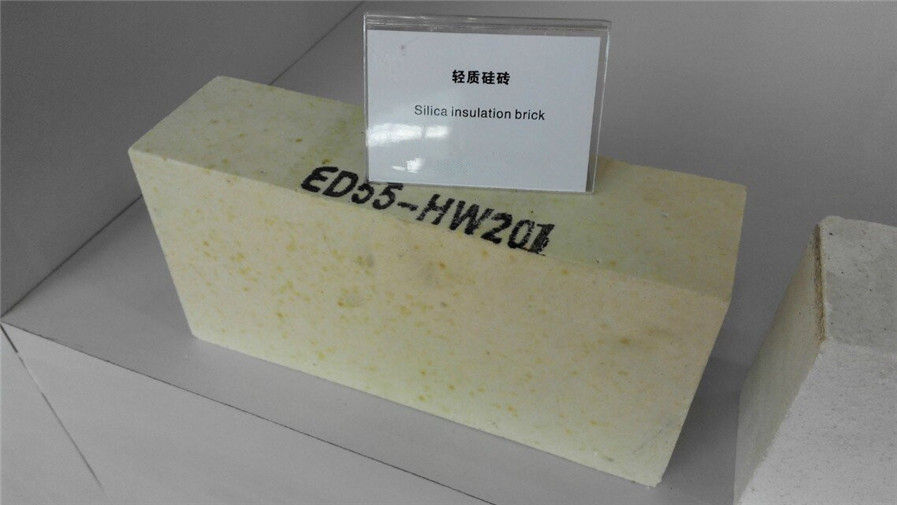

Heat Resistant Silica Refractory Bricks For Blast Furnace / Hot Blast Stove

Low Bulk Density Alumina Silica Fire Brick For Blast Furnace / Hot Blast Stove

Features

1. High refractoriness

2. Low thermal shock resistance

3. No pollution to glass liquid

4. Low bulk density

Applications

Light weight silica brick is mainly used to preserve heat in glass industry, iron&steel industry and ceramic furnace.

Physical properties and chemical composition

|

|

Item

|

QG-0.8

|

QG-1.0

|

QG-1.1

|

QG-1.15

|

QG-1.2

|

|

SiO2 %

|

≥88

|

≥91

|

≥91

|

≥91

|

≥91

|

|

Bulk Density g/cm3

|

≤0.85

|

≤1.00

|

≤1.10

|

≤1.15

|

≤1.20

|

|

Cold Crushing Strength Mpa

|

≥1.0

|

≥2.0

|

≥3.0

|

≥5.0

|

≥5.0

|

|

0.2Mpa Refractoriness Under Load T0.6 °C

|

≥1400

|

≥1420

|

≥1460

|

≥1500

|

≥1520

|

|

Permanent Linear Change On Reheating(%)1450°CX2h

|

0~+0.5

|

0~+0.5

|

0~+0.5

|

0~+0.5

|

0~+0.5

|

|

20-1000°C Thermal Expansich10-6/°C

|

1.3

|

1.3

|

1.3

|

1.3

|

1.3

|

|

Thermal Conductivity (W/MK) 350°C

|

0.55

|

0.55

|

0.60

|

0.65

|

0.70

|

|

|

|

|

|

|