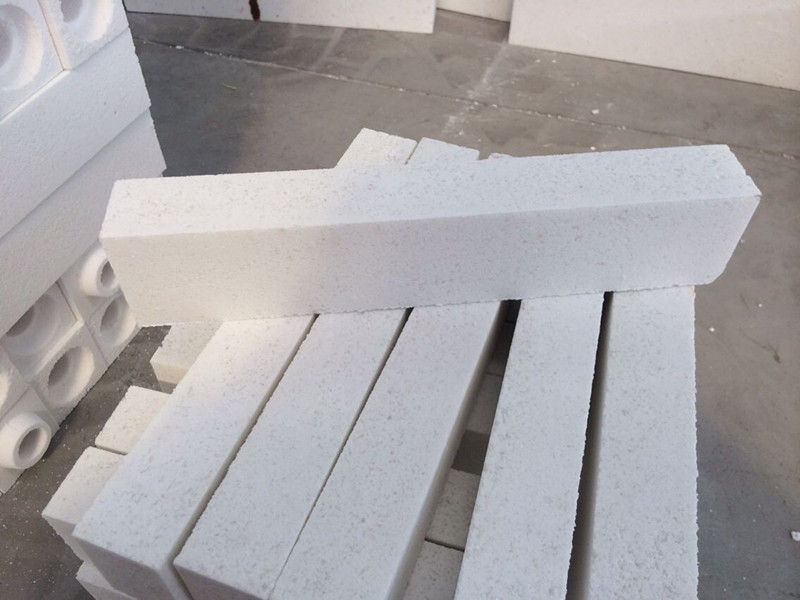

Good Wear Resistance and High Purity Corundum Brick for Glass Furnace / Gas Furnace

-

Parameters

-

Comments

| Bulk Density: | 3.1g/cm3 | Cold Crushing Strength: | 70 MPa |

|---|---|---|---|

| Color: | White | Al2O3: | 94% |

| SiO2: | 1.5% | Apparent Porosity: | 10% |

| Refractoriness: | 1875C | Origin: | China |

| Certificate: | CE, ISO |

High Strength and High Purity Corundum Brick for Glass Furnace, Gas Furnace, Ceramic Kiln

1.Description

Corundum Refractory material refers to the Al2O3 content of more than 90% of the products, also known as alumina refractory products, corundum hardness is very high (Mohs hardness 9), the melting point is also high. These are closely related to the firmness of the Al-O bonds in the structure. Therefore, the alpha-Al2O3 is the main phase of the composition of high temperature refractories and high temperature electrical insulating materials.

Corundum has good resistance to acid, alkaline slag, metal and glass melt. It is in the high temperature of the oxidizing atmosphere or in a reducing atmosphere used, can receive good results.

2.Applications

Corundum brick is mainly used for blast furnace and blast furnace hot blast stove, furnace refining furnace, sliding water apparatus, glass furnace, and petrochemical industrial furnaces, etc. Also widely used in petrochemical and chemical fertilizer industry of cracking, such as high temperature transformation furnace, metallurgical furnace lining, and kiln furniture.

3.Features

1.Load softening temperature greater than 1700℃.

2.Good chemical stability compression strength.

3.The slag resistance strong also can resist glass solution.

4.Good thermal shock stability and erosion resistance.

5. High compression strength.

6.High temperature creep rate is low and small thermal expansion coefficient.

4. Specification

| tem |

Corundum Brick 99 |

Corundum Brick 90 |

| Al2O3 % | ≥99 | ≥90 |

| SiO2 % | ≤0.2 | ≤8 |

| Fe2O3 % | ≤0.2 | ≤0.2 |

| Bulk Density g/cm3 | ≥3.2 | ≥3 |

| Apparent porosity % | ≤19 | ≤18 |

| Cold compressive strength MPa | ≥100 | ≥100 |

| (0.2Mpa,0.6%)Load softening began to temperature °C | ≥1700 | ≥1700 |