-

Parameters

-

Comments

| SiO2% ≥: | 94 | Fe2O3 %≥: | 0.8-1.2 |

|---|---|---|---|

| 0.2MPa RUL°C ≥: | 1650 |

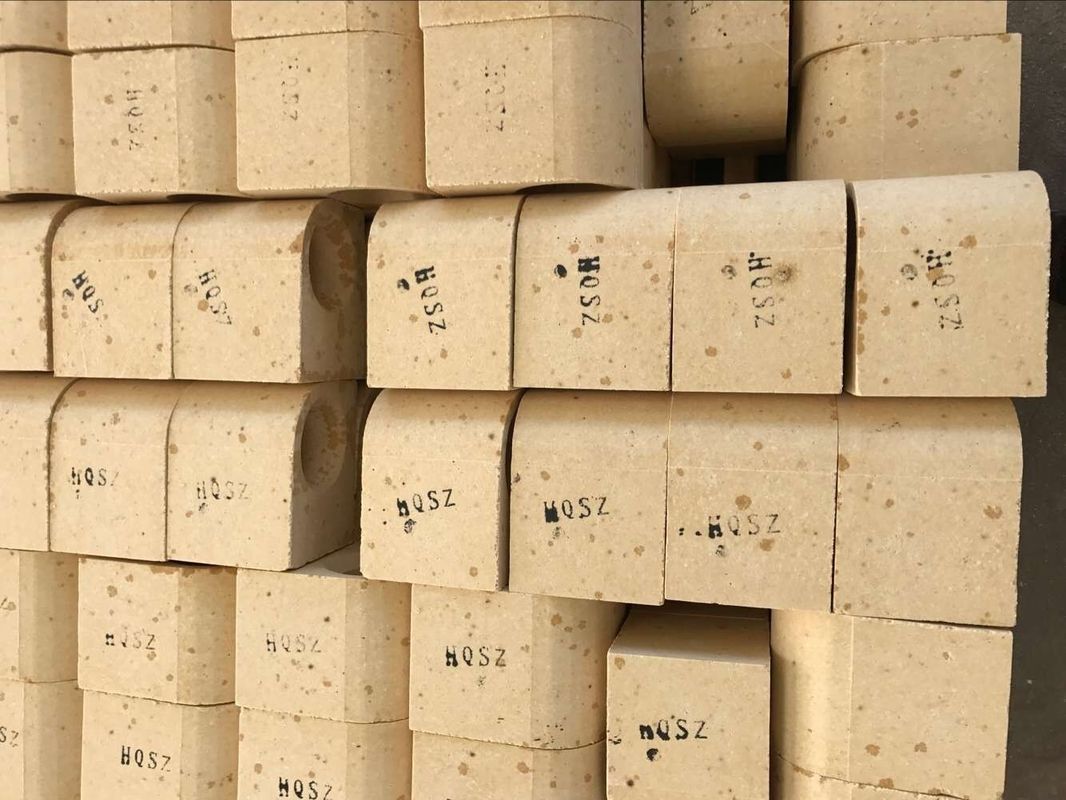

Description For Silica Brick:

Silica brick is made of quartz stone material, the content of SiO2 is above 93%,it has good resistance to acid slag and good heat conductivity. And the refractoriness is 1690~1710°C,RUL is beyond 1620°C.

SiO2 has different types of crystals in different temperatures, and the transform between the crystals will cause the change of the bulk. So there is a close contact between the changes of SiO2 crystals and the produce ,performance and usage of silica bricks. During the heating, there will be changes of the bulk ,and cristobalite changes most, then quartz, phosphorus quartz is the slowest of all and it also has good heat-conductivity.Coke oven should use the silica brick with small true density. And the phosphorus quartz is better than others.

Application For Silica Brick:

Mainly used in the construction of regenerative chamber, chute, combustion chamber, coking chamber, furnace roof etc. parts of the coke ovens.

Also be used for coke oven of coking chamber and combustion chamber partition, steel open hearth of regenerative chamber and sediment chamber, soaking furnace, glass melting furnace, refractory silica brick materials and ceramic firing kiln and kiln of the vault and other supporting parts. Also used in hot blast stove of high temperature bearing parts and acid open hearth furnace roof.

Advantage For Silica Brick:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products.

Physical And Chemical Indicators:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||