-

Parameters

-

Comments

| Bulk燿ensity: | 1.0g/cm3 | Cold燙rushing燬trength: | 2.0 |

|---|---|---|---|

| Thermal燾onductivity: | 0.25(W/m.k) | Al2O3: | 50 |

| Fe2O3: | 0.9 | Original: | China |

IM 23 Mullite Insulation Brick with High Strength for Gas Furnace

Description:

High temperature mullite insulation bricks for sale are made from good quality and superior raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chemical demands.

Features:

1. Lower content of iron, alkaline and impurities, good high temperature properties.

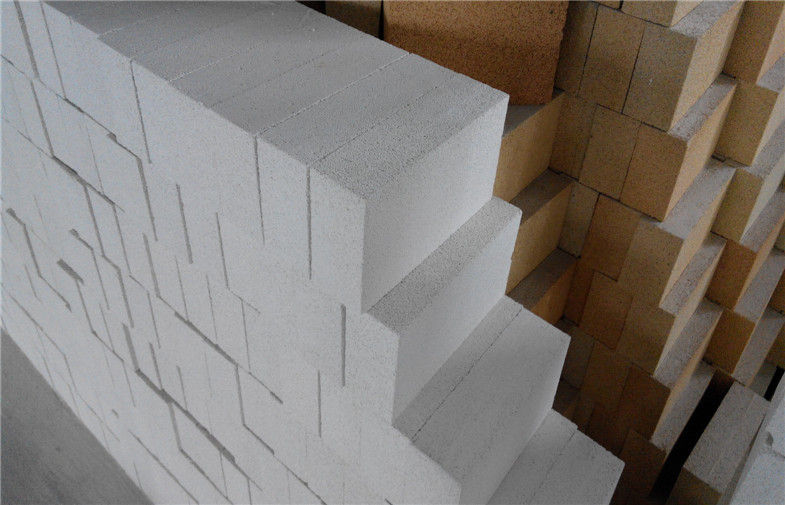

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

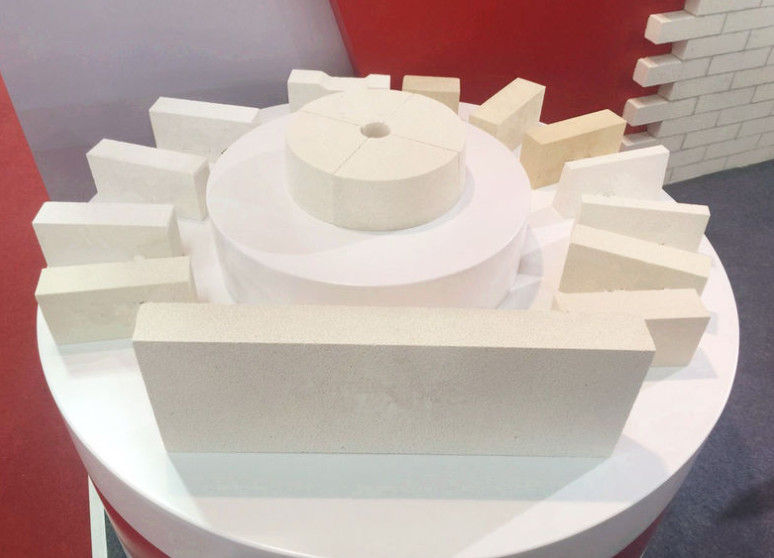

4. Precise sizes due to grinding and shaping after firing, which meets the requirement of construction.

Application:

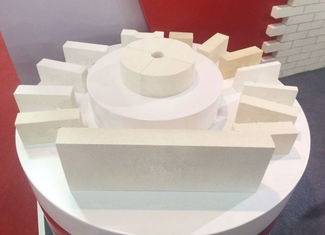

Mullite brick can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry, such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

Phyical and Chemical Index:

| Bulk density g/cm³ ≤ | 0.6 | 0.8 | 1 | 0.6 | 0.8 | 1 | 1 | 1.2 |

| Cold Crushing Strength Mpa ≥ | 1.5 | 2.5 | 4.2 | 1.5 | 3.2 | 4 | 4 | 5 |

| Thermal stability 1100°C (Air Cooling) % | 10 | 20 | 20 | 10 | 20 | 20 | 20 | 20 |

| Reheating linear change | 1300×12 | 1300×12 | 1300×12 | 1400×12 | 1400×12 | 1400×12 | 1500×12 | 1500×12 |

| Thermal conductivity 350±25°C (W/m.k) ≤ | 0.2 | 0.23 | 0.33 | 0.2 | 0.25 | 0.33 | 0.35 | 0.4 |

| Al2O3 % ≥ | 48 | 49 | 50 | 55 | 57 | 57 | 60 | 67 |

| Fe2O3 % ≥ | 0.9 | 0.9 | 0.9 | 0.8 | 0.8 | 0.8 | 0.7 | 0.6 |

Product Pictures: