-

Parameters

-

Comments

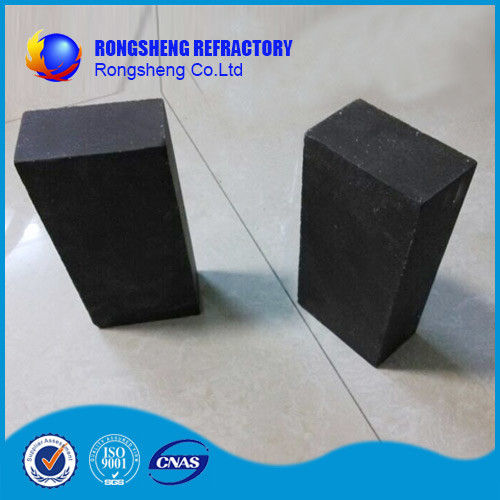

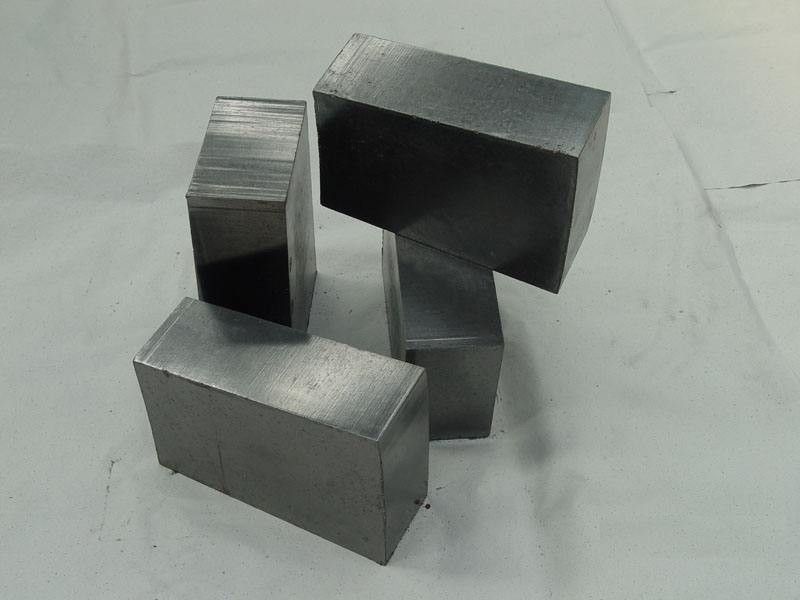

| Product Name: | Magnesium Bricks | Material: | Bauxite Chamotte |

|---|---|---|---|

| Shape: | Various | Color: | Black |

| Apparent Porosity: | 20 | Efractoriness: | 1450 |

230x100x65mm Size Magnesia Brick Direct Combination Magnesia Chorme Bricks Different Shape

Description:

Magnesia brick is alkaline refractory main products, the products high refractoriness of iron oxide, basic slag and high calcium flux has good erosion resistance properties. Widely used steel industry steelmaking furnace lining, the ferroalloy furnace, described. simple, colord metallurgy industry furnaces building materials industry kiln, glass industry regenerator grid body heat exchanger, refractories industrial tunnel kiln and high temperature firing kiln, etc.

Our Company:

Technical Function:

1. Low thermal conductivity and low heat storage;

2. Excellent thermal stability and thermal shock resistance

3. Excellent erosion resistance

4. Excellent heat insulation, fire proofing and processing function

Technical Date:

| Item | Common | Standard | H Pure | H Alumina | H Alumina + Zirconium | Zirconium | |

| Al2O3 (%) | 42~44 | 45~46 | 47~49 | 52~55 | 45~46 | 39~40 | |

| Al2O3 + SiO2 (%) | 96 | 97 | 99 | 99 | / | / | |

| Al2O3 + SiO2 + ZrO2 (%) | / | / | / | / | 99 | 99 | |

| ZrO2 (%) | / | / | / | / | 5~7 | 15~17 | |

| Fe2O3 (%) | 〈1.2 | 〈1.0 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Na2O + K2O (%) | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Refractoriness (℃) | 1110 | 1260 | 1260 | 1360 | 1360 | 1430 | |

| Working Temperature (℃) | 1000 | 1050 | 1100 | 1200 | 1260 | 1350 | |

| Density (kg/m3) | 96/128 | 96/128 | 96/128 | 128/160 | 128/160 | 128/160 | |

| Thermal Conductivity (w/m.k) (Density 128kg/m3) | -4(1000℃) | -3(1000℃) | -3(1100℃) | -3(1250℃) | 3(1250℃) | 3(1350℃) | |

| Rate of Liner (%) (24h, Density 128kg/m3) |

0.09(400℃) 0.176(800℃) |

0.09(400℃) 0.176(800℃) |

0.09(400℃) 0.176(800℃) 0.22(1000℃) |

0.132(600℃) 0.22(1000℃) |

0.132(600℃) 0.22(1000℃) |

0.176(800℃) 0.22(1000℃) |

|

| Tensile Strength (MPa) (Density 128g/m3) | 0.08~0.12 | 0.08~0.12 | 0.08~0.12 | 0.08~0.12 | 0.08~0.12 | 0.08~0.12 | |

| Size (mm) | Standard | 7200*610*25mm 3600*610*50mm | |||||

| Customized | Depending on customers’ special requirement | ||||||

Applications:

Ceramic Industry

Kiln car insulation and seals

Continuous and batch kilns

Steel Industry

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Furnace hot face repairs

Reheating furnace and ladle covers

Refining and petrochemical

Reformer and pyrolysis lining

Tube seals, gaskets and expansion joints

High temperature pipe, duct and turbine insulation

Crude oil heater linings

Power generation

Boiler insulation

Boiler doors

Reusable turbine covers

Expansion seals/pipe coverings

Others

Insulation of commercial dryers and ovens

Veneer over existing refractory

Stress relieving insulation

Glass furnace crown protection

Fire protection

Customer Visit:

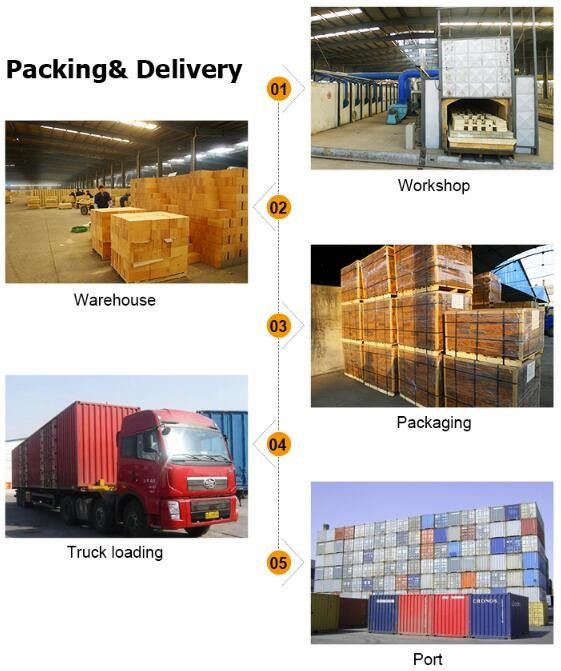

Packing And Delivery:

FAQ:

Q1: Is your Zhengzhou Rongsheng Refractory a manufacturer or trader?

A1: Manufacturer, some time we help our clients to purchase relevant products as a trader.

Q2: What’s the MOQ?

A2. No limitation.

Q3: How can we go to your Zhengzhou Rongsheng Refractory factory for visiting?

A3: (1). By Air: Zhengzhou International Airport

(2). By Fast Train: from Guangzhou to Zhengzhou, around 6 hours

from Shanghai to Zhengzhou, around 5 hours

from Beijing to Zhengzhou, around 3 hours

Q4: What’s the proportion of abroad business?

A4: Abroad market around 35%; Domestic market around 65%; and now export proportion is increasing.

Q5: Does your Zhengzhou Rongsheng Refractory provide turn-key projects?

A5: Yes, we already finished several turn-key projects at home and abroad.

Q6: Does your Zhengzhou Ronghseng Refractory supply samples?

A6: Yes, we can supply samples for free, and the freight will be undertaken by clients.