50% 60% 70% 80% high alumina clay for cement kiln copper aluminum melting induction furnace

-

Parameters

-

Comments

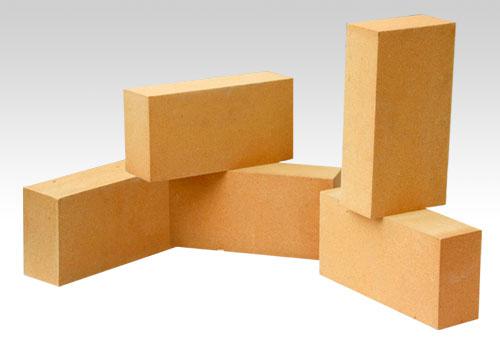

| Material: | Bauxite | Shape: | Brick |

|---|---|---|---|

| Item: | High Alumina Brick | Manufacturer: | Yes |

| Experience: | 30 Years | Color: | Faint Yellow |

| Applicnace: | Ladle, Kiln, Furnace | Refractoriness: | >1790℃ |

50% 60% 70% 80% high alumina clay for cement kiln copper aluminum melting induction furnace

Introduction of high alumina brick

High alumina brick is made by high grade bauxite, with unique advanced technology, the temperature of refractoriness under load is normally above 1420~1550°C , which is higher than the fireclay brick and it increases along with the AL2O3 content enhances.

Characteristices of high alumina brick

1. High intensity for pressure

2. Good thermal shock stability

3. Strong abrasion and corrosion resistance

4. High cold crushing strength

5. Excellent abrasion resistance at cold and hot conditions

Application of high alumina brick

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Physical and chemical indexes of high alumina brick

| Item | SK38 | SK37 | SK36 | SK35 |

| Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 |

| Fe2O3 % | ≤2 | ≤2 | ≤2 | ≤2 |

| Refractoriness °C | ≥1790 | ≥1770 | ≥1750 | ≥1420 |

| Apparent porosity % | ≤24 | ≤24 | ≤24 | ≤24 |

| Cold crushing strength Mpa | ≥53.9 | ≥49.0 | ≥44.1 | ≥39.2 |

| Refractoriness under load(0.2MPa) °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 |

| Reheating Linear Change % | +0.1(1500°C, 2h) | — | ||

| -0.4(1400°C, 2h) | — | |||

Our sweet service: Timely! Proffesional!

1. Quality assurance, RS REFRACTORY use high grade raw material and do strict inspect during the whole procession. All products adopt GB, ISO, ASTM,BS, JIS and DIN standard as per requirement. ISO, BV, TUV, SGS certified.

2. Provide professional designing solution, field technical assitance and any other consulting.

3. Price advantage, provided by manufacturer directly, save much intermediate fees.

4. Professional team, specialized in refractory production since 1986,with advanced technology and vast experience.

5. High production capacity, fast delivery of goods.

6. 24*7 online service.

7. OEM service available.

Zhengzhou Rongsheng Refractory Kiln Co.,Ltd.

1.Scale:factory and sales department including domestic market and foreign trade

2.Output: 180,000 ton refractory products

3.Output value: Reached 350million yuan

4.Number of staff: 500 people

5.Certification:IS09001:2000, ISO14001,BV and TUV certification

6.History: Specialized in manufacturing refractory products about 27 years

7.Main products: Shaped products such as refractory brick, refractory nozzle, ceramic fiber, slide gate, etc; unshaped products including repair, construction and casting mixes and mortars.

8.Trading nation: More than 20 countries, such as Thailand, Indonesia, Pakistan, Saudi Arabia, South Africa, Turkey, Iran, Iraq and so on.

FAQ

Frequently asked questions!

Q1: Are you a manufacture or trader?

A: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed, when to deliver?

A: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A: We have our own factories and excellent technical team, and we accept OEM service.

Q5: What certificates do you have?

A: ISO9001, BV and Test Report, also we can do other necessary certification according to your requirements.

Q6: Can you offer samples?

A: Of course, samples are total free! Freight should be paid by buyers.