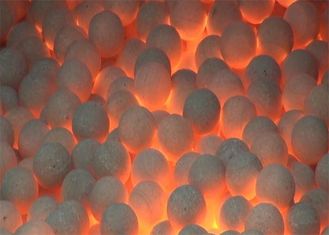

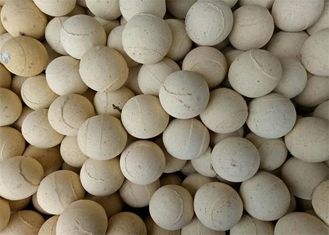

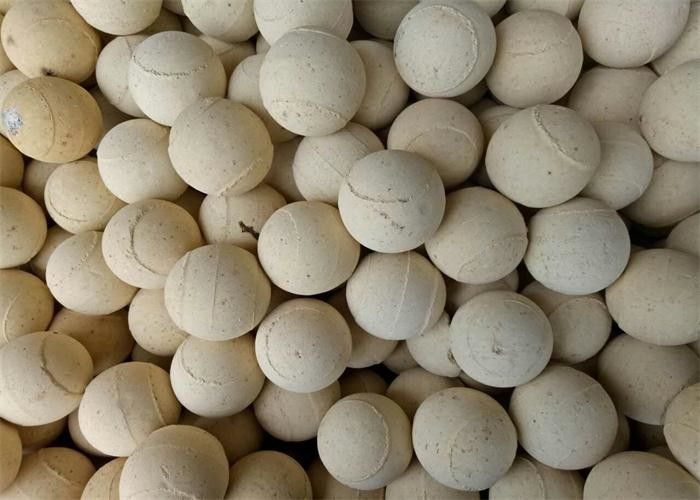

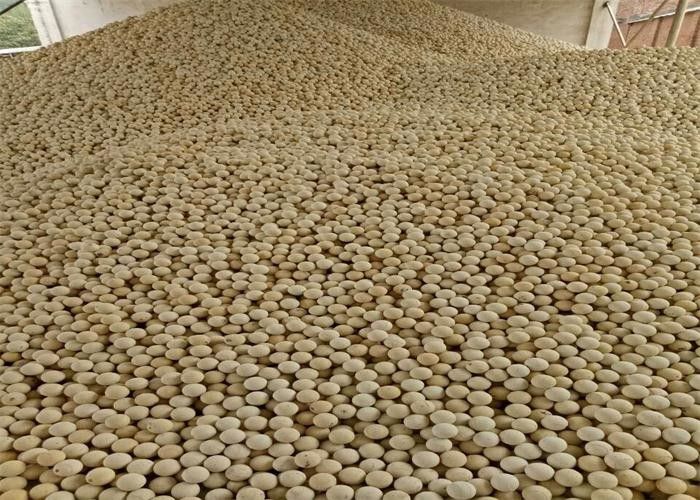

1900 Degree Size 405060 Refractory Ball For Hot Blast Stove High Temperature Resistance

-

Parameters

-

Comments

| Al2O3 ≥%: | 75 | AP ≤ %: | 22 |

|---|---|---|---|

| BD ≥g/cm3: | 2.4 | CCS ≥N/each Ball: | 16000 |

| Refractoriness ≥°C: | 1790 | PLC %: | 0.1-0.4 |

| Thermal Shock Resistance ≥each Time: | 40 |

1900 Degree Size 40,50,60 Refractory Ball For Hot Blast Stove , High Temperature Resistance

Features:

1High mechanical strength

2 Long service life

3Good chemical stability, no chemical reaction with the material;

4 High temperature resistance, can reach 1900 degrees

Applications:

1 Ordinary fire resistant ball is suitable for converter in sulphuric acid and chemical fertilizer industry.

2 High aluminum refractory ball, suitable for urea, iron and steel industries, such as hot blast stove, heating converter and other equipment.

Technical data

| Item/index/Materials | Al2O3 ≥% |

Fe2O3 ≤% |

MgO ≥% |

Cr2O3 % |

AP ≤ % |

BD ≥g/cm3 |

CCS

≥N/each ball |

Refracto

riness ≥°C |

PLC % | RUL≥°C | Thermal shock resistance ≥each time |

| Mullite ball | 75 | 22 | 2.4 | 16000 | 1790 | 0.1-0.4 | 1550 | 40 | |||

| Mg-Al ball | 5-10 | 85 | 18 | 2.85 | 18000 | 1790 | 1550 | 18 | |||

| High alumina ball | 75 | 1.5 | 23 | 2.55 | 20000 | 1790 | 1480 | 15 | |||

| High alumina 65 low creep ball | 65 | 1.5 | 22 | 2.6 | 15000 | 1790 | 0.1-0.4 | 1500 | |||

| high alumina 75 low creep ball | 75 | 1.5 | 21 | 2.65 | 15000 | 1790 | 0.1-0.4 | 1520 | |||

| Mg-Al chromium ball | 5-10 | 55 | 2 | 20 | 2.8 | 15000 | 1790 | 1520 | 15 | ||

| Mg-Al-Cr ball | 80 | 2 | 20 | 2.6 | 20000 | 1790 | 1520 | 15 |

Company information

Customer Visit