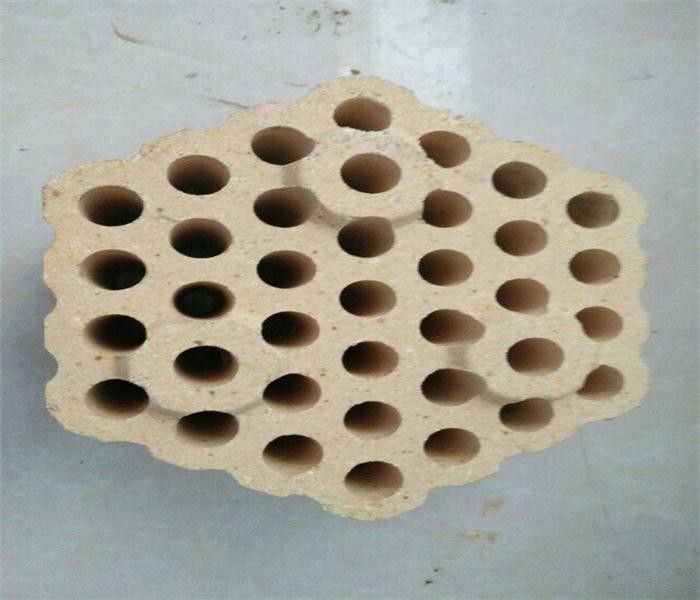

12 Holes Checker Fire Clay Bricks Lattice Insulating Fire Brick For Hot Blast Stove

-

Parameters

-

Comments

| Al2O3 %,≥: | 42-75 | Cold Crushing Strength, MPa ≥: | 20-54 |

|---|---|---|---|

| Apparent Porosity, % ≤: | 23-26 | Refractoriness Under Load, °C ≥: | 1300-1520 |

| Refractoriness, °C ≥: | 1730-1790 |

Fire Clay brick 12 Holes Checker Brick Lattice brick for Hot Blast Stove

Feature For Refractory Brick :

1. Low bulk density, low thermal conductivity, good thermal insulation performance.

2. Refractory category allow direct contact of fire, suitable ofr various atmosphere

3. Good integrity with furnace lining, long service life, easy operation, could be shaped freely

4. Product specification: standard form, normal standard, shaped and special shaped bricks.

5. Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Applications For Refractory Brick :

1. Furnaces of metallurgy industry, heat treatment furnace

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculating fluidized bed furnace

Physical Properties And Chemical Composition For Refractory Brick :

| Items | Index | ||||

| SK-38 | SK-37 | SK-36 | SK-35 | SK-34 | |

| Al2O3 %,≥ | 75 | 65 | 55 | 48 | 42 |

| Cold Crushing Strength, MPa ≥ | 54 | 49 | 44 | 40 | 20 |

| Apparent Porosity, % ≤ | 23 | 23 | 22 | 22 | 26 |

| Refractoriness Under Load, °C ≥ | 1520 | 1500 | 1470 | 1420 | 1300 |

| Linear Change on Reheating, [1500°C×2h]% | +0.1-0.4 | +0.1-0.4 | +0.1-0.4 | [1500°C×2h] +0.1-0.4 | 0-0.5 |

| Refractoriness, °C ≥ | 1790 | 1790 | 1770 |

1750 |

1730 |